Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Blog Article

Recognizing the Performance of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser serves as a crucial instrument in modern-day production, supplying precise, non-contact measurements that are important for maintaining rigorous industry criteria. By leveraging innovative laser technology, these analysers not only make certain minimal signal loss however additionally enhance the total efficiency of optical fibres.

Relevance of Optical Fibre Measurement

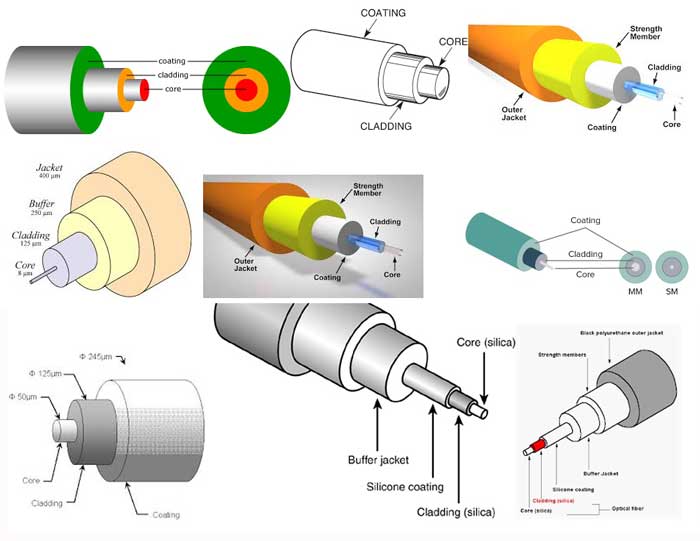

In modern-day manufacturing, the dimension of optical Fibre Diameter is crucial for ensuring the performance and reliability of Fibre optic systems. Exact Diameter measurement straight influences optical performance, as variants can bring about raised signal loss, lowered data transfer, and decreased total efficiency. The optical residential properties, consisting of light transmission and signal stability, are very delicate to the Fibre's Diameter, demanding accurate control during production.

Additionally, standardization in Fibre Diameter is important for compatibility and interoperability within varied telecommunications networks. As these networks broaden around the world, keeping uniformity in Fibre attributes promotes seamless assimilation across different elements and systems. Additionally, adhering to sector requirements worrying Diameter tolerances is important for manufacturers to meet regulatory demands and client assumptions.

Purchasing sophisticated measurement innovations not only boosts producing efficiency but likewise sustains high quality assurance procedures, making it possible for manufacturers to determine problems early in manufacturing. This positive technique lowers waste and ensures that the end products satisfy strict efficiency criteria. The significance of optical Fibre measurement can not be overemphasized, as it offers as a foundation for high-grade, trustworthy Fibre optic systems, which are indispensable to modern communication facilities.

How Diameter Analysers Job

The core operation relies upon the concept of light spreading and representation. As the laser light beam strikes the Fibre, variants in Diameter reason changes in the light's strength and wavelength (optical fibre diameter analyser). This information is processed in real-time using advanced formulas that equate the optical signals right into precise Diameter dimensions

Furthermore, many Diameter analysers are outfitted with numerous measurement factors along the Fibre, permitting an extensive evaluation of Diameter consistency. This is essential in making sure that the optical fibres satisfy rigorous market requirements. The whole process is automated, making it possible for high-speed dimensions and minimizing human error. The application of such modern technology dramatically improves high quality control in production, making certain that optical fibres are produced to precise requirements for optimal performance in their desired applications.

Trick Attributes to Think About

When selecting an optical Fibre Diameter analyser, numerous crucial functions require mindful factor to consider to make sure ideal efficiency and reliability. Initially, dimension precision is extremely important; the analyser needs to supply exact Diameter readings, generally in micrometers, to satisfy rigorous manufacturing specs. Additionally, why not check here a wide dimension array improves versatility, suiting different Fibre types and densities.

An additional vital attribute is the analyser's speed. Fast measurement abilities enable raised throughput, important in high-volume manufacturing atmospheres. In addition, real-time information processing and responses capacities make it possible for instant modifications, boosting quality assurance.

Interface and software application compatibility are additionally substantial considerations. An user-friendly interface improves operation, while durable software assistance assists in data evaluation and integration with existing production systems. The ability to export data in numerous layouts can boost coverage and compliance initiatives.

Additionally, toughness and maintenance requirements ought to be reviewed. An analyser constructed from premium materials will withstand the rigours of a production setting, while ease of upkeep guarantees long life and decreases downtime. Think about the degree of technical support and training provided by the maker, as this can significantly impact the reliable usage of the analyser in manufacturing settings.

Advantages in Manufacturing Efficiency

Enhancing manufacturing efficiency depends upon the integration of innovative modern technologies, such as optical Fibre Diameter analysers. These instruments play an essential duty in making certain that optical fibres meet rigorous quality standards, which is necessary for ideal efficiency in different applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, manufacturers can promptly identify and remedy variances from defined tolerances, thus reducing waste and minimizing the danger of faulty items

In addition, the early detection of possible issues causes reduced downtime and upkeep prices, consequently maximizing source allowance. Ultimately, the efficiency gains recognized via using optical Fibre Diameter analysers contribute to an extra affordable production setting, making certain that firms can supply top notch items while keeping cost-effectiveness and responsiveness to market demands.

Applications Throughout Industries

The versatility of optical Fibre Diameter analysers expands beyond manufacturing performance, locating applications across numerous markets that rely upon optical Fibre innovation. In telecommunications, these analysers are critical for guaranteeing the ideal efficiency More about the author of Fibre optic cables, straight affecting data transmission prices and network integrity. By accurately determining Fibre sizes, drivers can lessen signal loss and enhance total communication quality.

The medical industry additionally profits considerably from these tools, particularly in the advancement of endoscopic tools and laser treatments. Precise Diameter dimensions are crucial for developing effective optical fibers that are used in minimally intrusive procedures, enhancing person outcomes with enhanced imaging and treatment abilities.

In aerospace, the analysers play an important function in the manufacturing of light-weight, high-strength materials, where Fibre optics are integrated right into structural parts for tracking and diagnostics. Furthermore, the vehicle sector utilizes these gadgets to guarantee the integrity of Fibre optic sensing units that improve safety and security and performance features in lorries.

Conclusion

To conclude, the optical Fibre Diameter analyser is essential for contemporary manufacturing, ensuring exact dimensions that promote market criteria. Its sophisticated laser Home Page modern technology and real-time data handling abilities boost quality control and functional effectiveness. By automating the dimension process, manufacturers can quickly discover deviations, thereby decreasing signal loss and manufacturing downtime. The diverse applications throughout various markets emphasize the analyser's value in advertising constant renovation and data-driven decision-making within the production market (optical fibre diameter analyser).

In modern-day production, the dimension of optical Fibre Diameter is vital for making sure the efficiency and reliability of Fibre optic systems. The relevance of optical Fibre measurement can not be overemphasized, as it serves as a foundation for top notch, dependable Fibre optic systems, which are essential to modern interaction framework.

Diameter analysers employ sophisticated optical modern technologies to properly determine the Diameter of optical fibers.In addition, lots of Diameter analysers are equipped with several measurement factors along the Fibre, permitting for a detailed analysis of Diameter consistency.The flexibility of optical Fibre Diameter analysers extends past manufacturing effectiveness, locating applications across different markets that count on optical Fibre modern technology.

Report this page